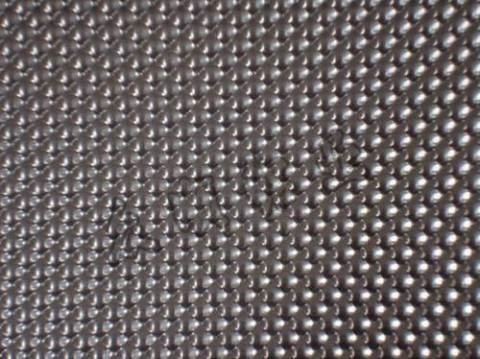

1060H24球形花纹铝板

单面半圆球花纹铝板(用于汽车排气管隔热板冲压件、汽车排气管隔热板部件)

铝合金牌号:1060-O、1050-O

规格及参数:宽度≤1000mm,厚度0.2mm~1.0mm,长度:片状或卷材。

使用范围: 适合生产各类汽车发动机隔热罩冲压件,隔热罩零件、发动机隔热板,汽车水箱、排气管隔热板部件等。产品最终已服务于广汽、大众、福特、江淮、通用等汽车上。

包装: 木托塑料布简包

技术参数: 棍体采用实心锻打钢材作为棍体,(半圆球花纹铝板)的压花设备

压辊直径500mm,设备总长度是1600mm我公司能加工后的范围是0.2-1.0mm,材料为软状态。最宽可以加工到1350mm。

执行标准:GB/T3880-2012.2,材质是1050A0态,此材料是适合汽车排气管防护罩之用途的,具有导热 散热效果好,耐腐蚀,重量轻等优点。

铝板力学性能按照GB/T3880.2,边部无毛刺无锐边。,抗拉强度65-95,延伸大于22.

山东众顺铝业生产的半圆球花纹铝板优势:

①、密度小。

半圆球花纹铝板,纯铝的密度是2.71kg/每立方米,仅为钢铁密度的三分之一,AL-mg,合金的密度更低。因此同等重量同等厚度桔皮花纹铝卷和钢材比较就多出三分之二的平方数。

②、抗腐蚀。

半圆球花纹铝板表面覆有一层致密坚硬的无色透明的氧化膜,能抵抗风云,食品,天然气,等侵蚀。橘皮(桔皮)纹铝卷铝板如果经过化学处理或者阳极氧化处理后,可以增加氧化膜的厚度,一般氧化膜厚度5-15微米,大大增强了橘皮(桔皮)纹铝卷铝板表面抗腐蚀性,并可以利用阳极氧化膜的多孔结构,吸附染料和重金属离子,染成各种悦目耐晒的颜色。

③、足够的强度。

半圆球花纹铝板有足够的轻度可以用于汽车发动机和排气管隔热防护罩等行业。通过合金化和退火可以使铝的强度或者抗拉强度进一步提升。无发脆现象。非常适合再次冲压成型。

④、反射率高。

半圆球花纹铝板工业纯铝对红外线和可见光的反射率在80%以上,铝含量约纯反射率越高,并且抗腐蚀性能越好。

⑤、电导性和热导性好。

半圆球花纹铝板纯铝的电导率相当于铜的62%,热导率相当于铜的60%,而密度只相当于铜的30%。

⑥、延展性好。

半圆球花纹铝板纯铝和变形铝合金可以进行冲压拉伸 深冲等压力加工,制成各种形状和很薄的产品。

⑦、回收率高。

半圆球花纹铝板的废料可以直接投炉使用,回收铝和冶炼铝相比可以节约能源95%。